ALWAYS FOCUSSED ON THE CUSTOMER

ALWAYS FOCUSSED ON THE CUSTOMER

WHAT WE OFFER

As well as being ceramic bodies manufacturers we also offer specialised services in the field of ceramics. We offer a wide range of services, from developing new products, characterisation of raw materials, personalised treatments of materials (milling, cruising, spray drying) and consultations on industrial processes.

WHAT WE OFFER

As well as being ceramic bodies manufacturers we also offer specialised services in the field of ceramics. We offer a wide range of services, from developing new products, characterisation of raw materials, personalised treatments of materials (milling, cruising, spray drying) and consultations on industrial processes.

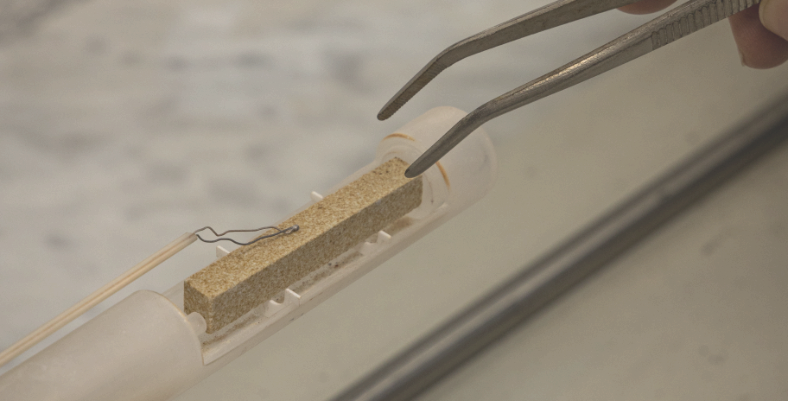

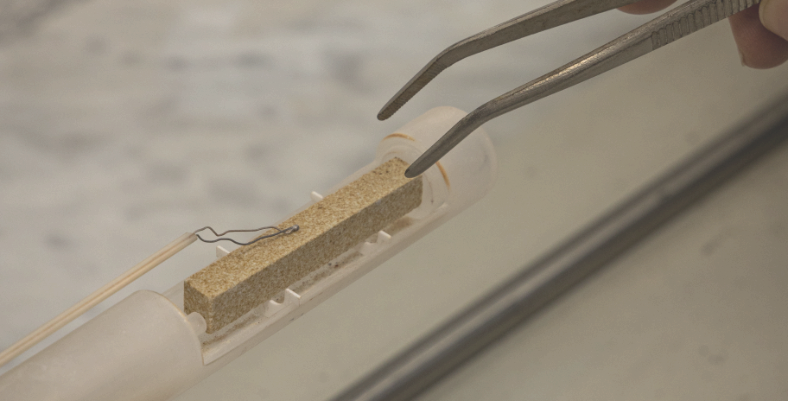

PERSONALISED COMPOSITIONS

VICAR offers the possibility of developing new compositions based on their customer requirements. Once the technical characteristics of the desired material has been evaluated, as well as its manufacturing process, a sample is prepared and sent to the customer for testing.

LABORATORY SERVICES

We offer physicochemical tests of raw materials and manufactured products. Contact us to consult the list of available assays.

PERSONALISED COMPOSITIONS

VICAR offers the possibility of developing new compositions based on their customer requirements. Once the technical characteristics of the desired material has been evaluated, as well as its manufacturing process, a sample is prepared and sent to the customer for testing.

LABORATORY SERVICES

We offer physicochemical tests of raw materials and manufactured products. Contact us to consult the list of available assays.

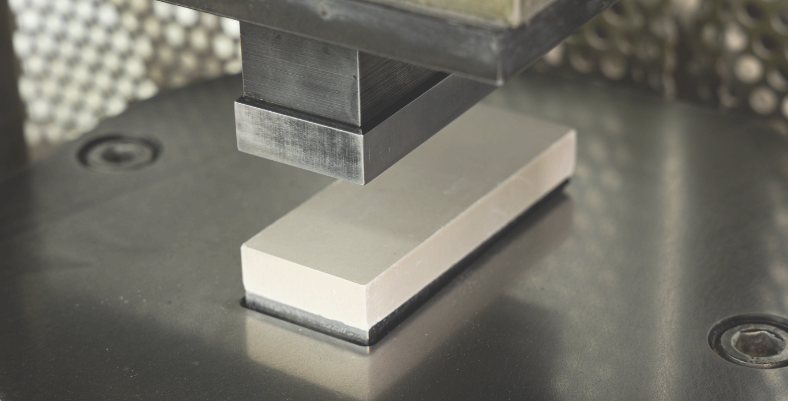

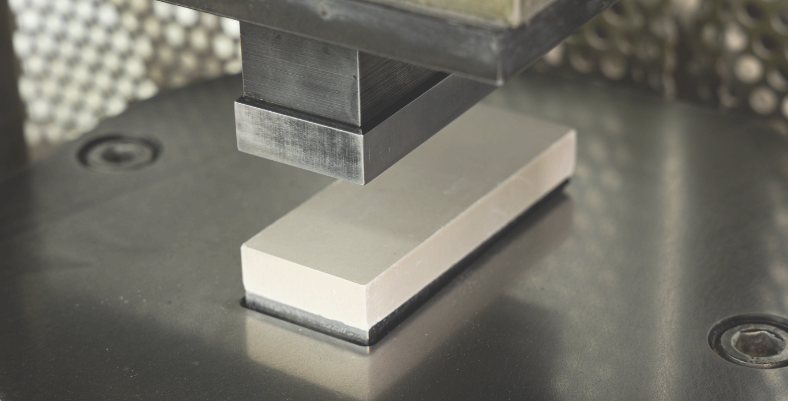

MATERIAL CHARACTERISATION

This service is ideal for technical applications to assist in the development and optimisation of new products.

INDUSTRIAL PROCESS CONSULTATIONS

Our technical team is trained to improve current processes, as well as implement new initiatives and developments. We can help guide you from the initial concept, to product development in the laboratory and to pilot test batches at a pilot plant prior to manufacturing the product on an industrial scale.

MATERIAL CHARACTERISATION

This service is ideal for technical applications to assist in the development and optimisation of new products.

INDUSTRIAL PROCESS CONSULTATIONS

Our technical team is trained to improve current processes, as well as implement new initiatives and developments. We can help guide you from the initial concept, to product development in the laboratory and to pilot test batches at a pilot plant prior to manufacturing the product on an industrial scale.

TREATMENTS

Mixing, wet grinding, sieving, spray drying, filter pressing, crushing and granulating processes.

VICAR offers various processes:

+ Mixing mineral and ceramic powders. We guarantee an intensive and homogeneous mixture.

+ Crushing of clay materials and soft minerals to sizes less than 5mm.

+ Hammer milling of minerals to sizes smaller than 1mm.

+ Sieving of slips with deferrising.

+ Filtering of ceramic formulations and presentation in plastic masses.

+ Spray drying. We use spray dryers which provide an average product size of 80-400 microns, with production capacities ranging from 100 to 1000 litres of evaporated water per hour.

TREATMENTS

Mixing, wet grinding, sieving, spray drying, filter pressing, crushing and granulating processes.

VICAR offers various processes:

+ Mixing mineral and ceramic powders. We guarantee an intensive and homogeneous mixture.

+ Crushing of clay materials and soft minerals to sizes less than 5mm.

+ Hammer milling of minerals to sizes smaller than 1mm.

+ Sieving of slips with deferrising.

+ Filtering of ceramic formulations and presentation in plastic masses.

+ Spray drying. We use spray dryers which provide an average product size of 80-400 microns, with production capacities ranging from 100 to 1000 litres of evaporated water per hour.